Sidewalk Repair

Damaged Sidewalks

Safety Concerns

Uneven surfaces, cracks, and potholes can create tripping hazards, particularly for pedestrians with mobility challenges, the elderly, and children.

Liability

Neglected sidewalks can lead to legal issues for property owners, municipalities, and businesses if accidents occur due to their poor condition.

Aesthetics

The appearance of sidewalks contributes to the overall visual appeal of a neighborhood. Damaged sidewalks can detract from the beauty of the surroundings.

Property Value

Well-maintained sidewalks can enhance the value of properties within a community. Conversely, neglected sidewalks can have a negative impact on property values.

Benefits of Sidewalk Repair

Safety Enhancement

Repairing sidewalks ensures a smooth and even walking surface, reducing the risk of accidents and injuries.

Accessibility

Well-maintained sidewalks accommodate individuals with disabilities, ensuring equal access to public spaces and services.

Community Pride

Properly repaired sidewalks contribute to a sense of pride and unity within a neighborhood, fostering a positive environment.

Longevity

Timely repairs extend the lifespan of sidewalks, saving costs associated with more extensive reconstruction in the future.

Repairing a Sidewalk

Assessment and Planning

Once the assessment is complete, a plan for repair is developed. This plan should consider the type and severity of damage, budget constraints, local regulations, and the desired timeline for completion.

Obtain Permits

In some cases, permission may be required from adjacent property owners if the sidewalk repair involves access to private property or impacts neighboring structures.

Preparation

If necessary, mark off the area to be repaired using caution tape or traffic cones to ensure safety and minimize disruption to pedestrian traffic.

Demolition

Exercise caution to avoid damaging adjacent structures, utilities, or underground infrastructure during the demolition process.

SubBase Preparation

If the subbase is unstable or prone to erosion, consider adding a layer of gravel or crushed stone to improve drainage and support.

Form Installation

In some cases, formwork may be necessary to create the desired shape and dimensions for the new sidewalk section. Install wooden or metal forms along the edges of the repair area to contain the concrete during pouring and curing.

Pouring and Finishing

After pouring, use a screed or bull float to level the concrete and remove excess material. Finish the surface with a trowel to create a smooth and even texture.

Curing and Protection

Protect the repair area from foot traffic, vehicles, and inclement weather during the curing period to prevent damage and ensure a durable, long-lasting sidewalk.

Cleanup

Clean the repair area and surrounding pavement to remove any residue or stains from the repair process, leaving the sidewalk looking neat and well-maintained.

Final Inspection

Finally, inspect the repaired sidewalk to ensure that the work meets quality standards and complies with local regulations. Address any deficiencies or issues promptly to prevent further damage and ensure safety for pedestrians.

Sidewalk Construction

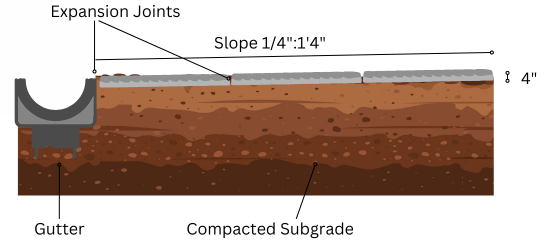

Base Placement

A solid foundation is critical for the longevity of a sidewalk. Before pouring concrete, the ground should be properly prepared. Adequate base preparation helps prevent settling, cracking, and uneven surfaces over time.

Concrete Mix

The concrete mix used for sidewalks should be appropriate for the local climate and conditions. The right mix ensures that the concrete will withstand freeze-thaw cycles, temperature fluctuations, and heavy pedestrian traffic.

Expansion Joints

Expansion joints are gaps intentionally created in the concrete at regular intervals to allow for natural expansion and contraction due to temperature changes. These joints help prevent cracks from forming as the concrete shifts.

Quality Materials and Quality Workmanship

Cement

Cement is a fine powder made from limestone, clay, and other minerals. It is a binding agent that, when mixed with water and aggregates, forms the paste that hardens and binds the concrete mix.

Aggregates

Aggregates are granular materials like sand, gravel, crushed stone, or recycled concrete. They provide strength and volume to the concrete mixture.

Admixtures

Admixtures are chemicals added to the concrete mix to modify its properties. They can enhance workability, reduce water content, accelerate or retard setting time, and improve durability.

Reinforcement

Reinforcement materials, such as steel bars (rebar) or fibers, are often added to concrete to increase its tensile strength and prevent cracking.

Asphalt Binder

Asphalt binder is a sticky, black, and viscous petroleum-based substance. It acts as a glue to hold the aggregate particles together in asphalt pavement. There are different types of asphalt binders, including hot mix asphalt (HMA) and cold mix asphalt (CMA).

Fillers & Modifiers

Fillers, such as mineral dust or fine sand, may be added to asphalt mixes to improve their properties. Modifiers, like polymers or rubber, can enhance asphalt’s flexibility, durability, and resistance to cracking.

Aggregate Gradation

The specific grading and size distribution of aggregates are crucial for the performance of asphalt. A well-graded mix ensures proper compaction and durability.

Anti-Stripping Agents

Anti-stripping agents are additives that help prevent moisture-related damage by improving the adhesion between the asphalt binder and the aggregates..

Asphalt Recycling Agents

These agents facilitate the reuse of old asphalt pavement materials in new mixes, promoting sustainability and reducing waste..

Fibers

Similar to concrete, asphalt can also benefit from the addition of fibers, such as polyester or glass fibers, to enhance its toughness and resistance to cracking..

The Washington State Masonry Compnay

Why Choose Us?

Expertise

Our company boasts extensive experience and expertise in concrete and asphalt repair, with a proven track record of successfully completing projects of varying sizes and complexities.

Quality Workmanship

We pride ourselves on delivering high-quality workmanship, utilizing the latest techniques, tools, and materials to ensure durable and long-lasting repairs.

Custom Solutions

We understand that every repair project is unique, which is why we offer customized solutions tailored to meet the specific needs and requirements of our clients.

Timely Service

We prioritize efficiency and timely service, striving to complete repair projects on schedule and minimize disruption to our clients’ daily operations or routines.

Competitive Pricing

Our competitive pricing ensures that clients receive exceptional value for their investment, with transparent pricing and no hidden costs.

Customer Satisfaction

Customer satisfaction is our top priority. We are committed to delivering superior service, exceeding expectations, and building long-term relationships with our clients.

LIcensed and Insured

Our company is fully licensed and insured, providing peace of mind and assurance that repair projects are conducted safely and in compliance with regulations.

Proven Track Record

Concrete

Asphalt

Cost

Durability

Maintenance

Curb Appeal

Environmental Impact

Installation Time

Asphalt installation is faster, with shorter curing times. Asphalt surfaces can be ready for use within a day or two after installation, minimizing downtime and disruption.

Residential and Commercial Services

Residential Asphalt and Concrete Services

Driveways and Walkways Washington State Masonry Company specializes in constructing durable and aesthetically pleasing driveways and walkways. Using top-quality asphalt and concrete materials, they ensure smooth, long-lasting surfaces that can withstand heavy use and harsh weather conditions. Their team works closely with homeowners to design and implement custom layouts that enhance curb appeal and property value.

Read More

Commercial Asphalt and Concrete Services

Parking Lots The company provides professional asphalt and concrete parking lot construction for commercial properties. Their services include site preparation, grading, and paving, ensuring a smooth, durable surface that can handle high traffic volumes. They also offer maintenance and repair services to keep parking lots in optimal condition.

Read More

By offering a comprehensive range of residential and commercial asphalt and concrete construction services, Washington State Masonry Company ensures high-quality results that meet the diverse needs of their clients.

FAQs

Q: What are the main differences between asphalt and concrete for sidewalks and driveways?

A: Asphalt is typically black and flexible, while concrete is gray and rigid.

Asphalt is more affordable but requires more maintenance.

Concrete is durable and long-lasting but can be more expensive upfront.

Q: How often should I seal my asphalt driveway, and why is it necessary?

A: Generally, you should seal an asphalt driveway every 2-3 years to protect it from moisture, UV rays, and wear and tear. Sealing extends its lifespan.

Q: How can I prevent cracks in my concrete sidewalk or driveway?

A: Proper installation with reinforced steel.

Regular sealing to prevent moisture penetration.

Avoiding heavy loads and abrupt temperature changes.

Q: What causes cracks in asphalt driveways, and how can I repair them?

A: Cracks in asphalt can be caused by water infiltration, temperature fluctuations, and heavy loads. Smaller cracks can be repaired with crack sealant, while larger ones may require patching.

Shop Masonry Services

Fireplaces

Materials

Chimneys

Walls

Cleaning

The Washington State

Masonry Company

License No. BRICKBD809Q4

Same day or same week estimates and completions

5 year warranty on all workmanship

Based out of Federal Way, WA

Call Us At: 206-437-6582